Thank you for visiting the Finch & Beak website. Finch & Beak is now part of SLR Consulting, a global organization that supports its clients on setting sustainability strategies and seeing them through to implementation.

This is an exciting time for us, as our team now includes an array of new colleagues who offer advisory and technical skills that are complementary to our own including Climate Resilience & Net Zero, Natural Capital & Biodiversity, Social & Community Impact, and Responsible Sourcing.

We would like to take this opportunity to invite you to check out the SLR website, so you can see the full potential of what we are now able to offer.

ISO 14040 defined LCA in 1997 to be the ‘compilation and evaluation of the inputs, outputs and the potential environmental impacts of a product system throughout its life cycle’. These days, the LCA method is applied equally to processes and services as well as products, and can be extended into social as well as environmental considerations. When done well, by simultaneously examining multiple criteria across the full life cycle, LCA helps avoids burden-shifting, whereby well-meaning intentions to address one impact may have unintended consequences on other criteria or elsewhere in the life cycle.

For example, when the Environment Agency looked into the environmental impacts of carrier bags[1], back in 2011, they found that cotton bags needed to be reused over 130 times before they had a lower climate change impact than traditional single-use plastic bags. Introduce even a very modest level of reuse (three times) of the latter and that threshold rose to nearly 400 uses. Supermarkets were (naturally) very happy to sell customers the cotton bags (rather than give away the plastic ones), but (it appears) they were not doing so for the benefit of the environment.

An LCA provides an invaluable, evidence-based assessment of the impacts of your product, processes, and services. Once complete, this evidence base can be used to direct improvements that reduce material use, improve supply chain resilience, protect natural capital and reduce waste.

There are three principal reasons clients come to SLR requiring an LCA:

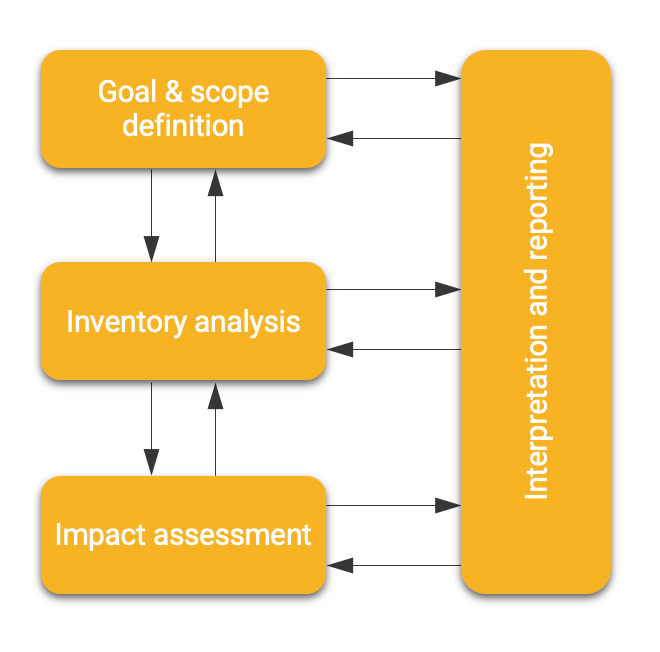

The ISO method recommends an iterative, four-step approach that we still follow today.

The arrows denote that the process is very much meant to be iterative, with findings at each stage liable to prompt revisiting other steps to finesse the analysis.

A full ISO-compliant LCA is a fair undertaking, so most of my clients over the past 15 years have preferred to commission a streamlined assessment. These may reduce the number of criteria assessed (frequently to climate change alone – a carbon footprint) and/or not look across the whole life cycle. This can make the project more manageable, in terms of data requirements, timescales (typically 3-6 months) and therefore associated cost.

The most prevalent application of LCA for organizations these days is the corporate carbon footprint. Following guidelines such as the GHG Protocol, we assist companies in determining their baseline impact and then how to systematically reduce their emissions. These studies often invoke the Science-Based Targets Initiative, and the most ambitious seek to deliver climate strategies for our clients that culminate in their reaching Net Zero emissions.

Suppose you are a manufacturing sustainability manager leading your organization’s greener manufacturing journey, at the start of the process, the task before you can be daunting.

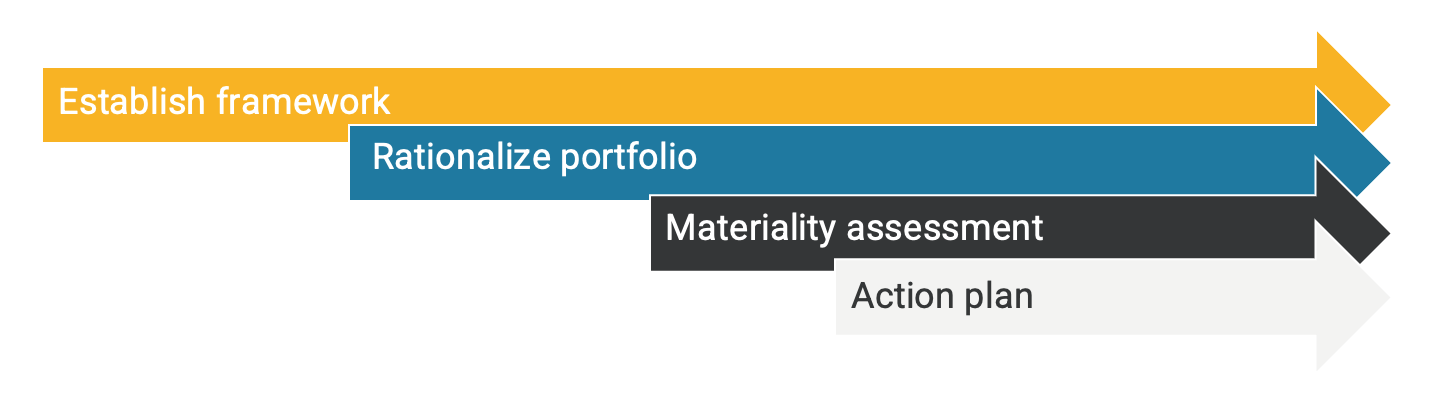

Faced with all the different considerations, it can be hard to know where to start. Using an LCA as starting point of the process to make your products greener will provide a framework with accurate questions and clarify the sequence of the right steps to be taken, as illustrated by the diagram below.

If your fundamental goal is to make your products greener, I elaborate on the four steps to take in the download at the top of this article.

As of March 2022, Finch & Beak has joined SLR to further the acceleration of sustainability.

If your organization is considering conducting an LCA or materiality assessment or requires other support in accelerating your sustainability and improving your ESG performance reach out to Johana Schlotter, at johana@finchandbeak.com or call +31 6 28 02 18 80 to discuss how Finch & Beak can support you in meeting your ambitions.

This article was written by Simon Gandy, Technical Director, Sustainability at SLR.

Photo by Arno Senoner on Unsplash

Finch & Beak

hello@finchandbeak.com

+34 627 788 170